Turboexpander-compressor ADKG-10For low and medium flow rates

Up to 5 MM m³/h

Up to -170°С

Up to 13.5 MPa

Magnetic suspension

The benchmark solution in its segment with proven performance and reliability for low and medium flow rates. It is the quintessence of our years of experience.

It is an essential element of technological designs and can be used to cool natural gas in low temperature separation cycles, fractional condensation separation, cyclo-ORC, dehydrogenation, liquefaction and other gas-bearing chemical processes.

It can be installed indoors at room temperatures of +5 .. +45 oC (UHL4 as per GOST 15150-69) and is designed as a monoblock with a horizontal shell connector. A single-stage centrifugal compressor and an axial turbine, usually single-stage with an inlet guide nozzle, are installed on the rotor of the replaceable flow part.

| Frame size | |

| Shell connector | Horizontal |

| Bearings | Active magnetic |

| Gas flow, MMm3 / d | 3...12 |

| Inlet pressure, MPa | 6...13.5 |

| Temperature, °C | -5…-170 |

| Rotation frequency, rpm | 12000…17000 |

| Power on the shaft, kW | 700…7300 |

| Compressor | |

|---|---|

| Compression level | 1.46 max |

| Adiabatic efficiency, % | 80 min |

| Polytropic efficiency, % | 82 min |

| Turbine | |

| Expansion level | 2.3 max |

| Adiabatic efficiency, % | 80 min |

| Nozzle adjustment range, % | 8-20 |

| Equipment | Length, mm | Width, mm | Height, mm | Weight, kg |

|---|---|---|---|---|

| ADKG-10 | 3000 | 2700 | 2400 | 8000 |

-

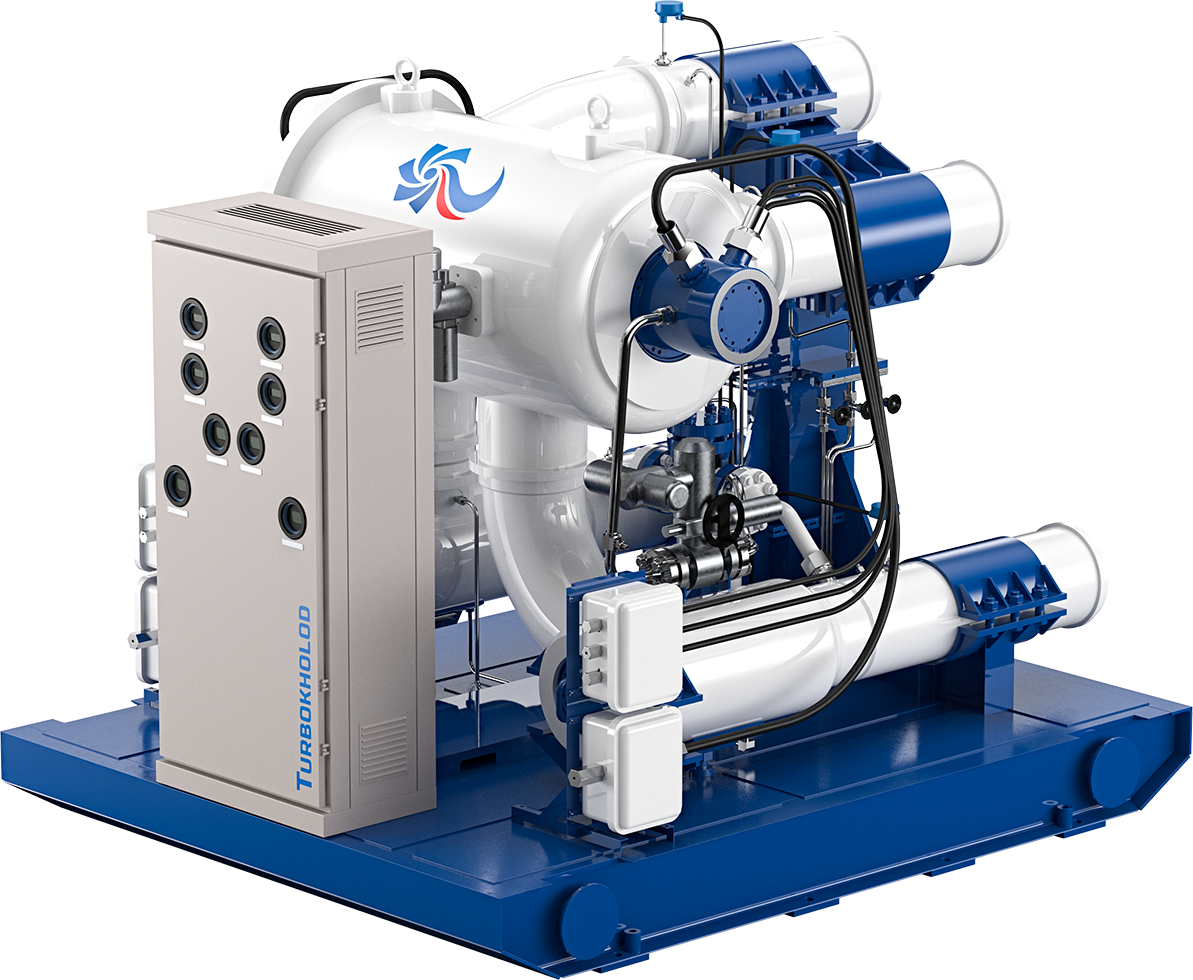

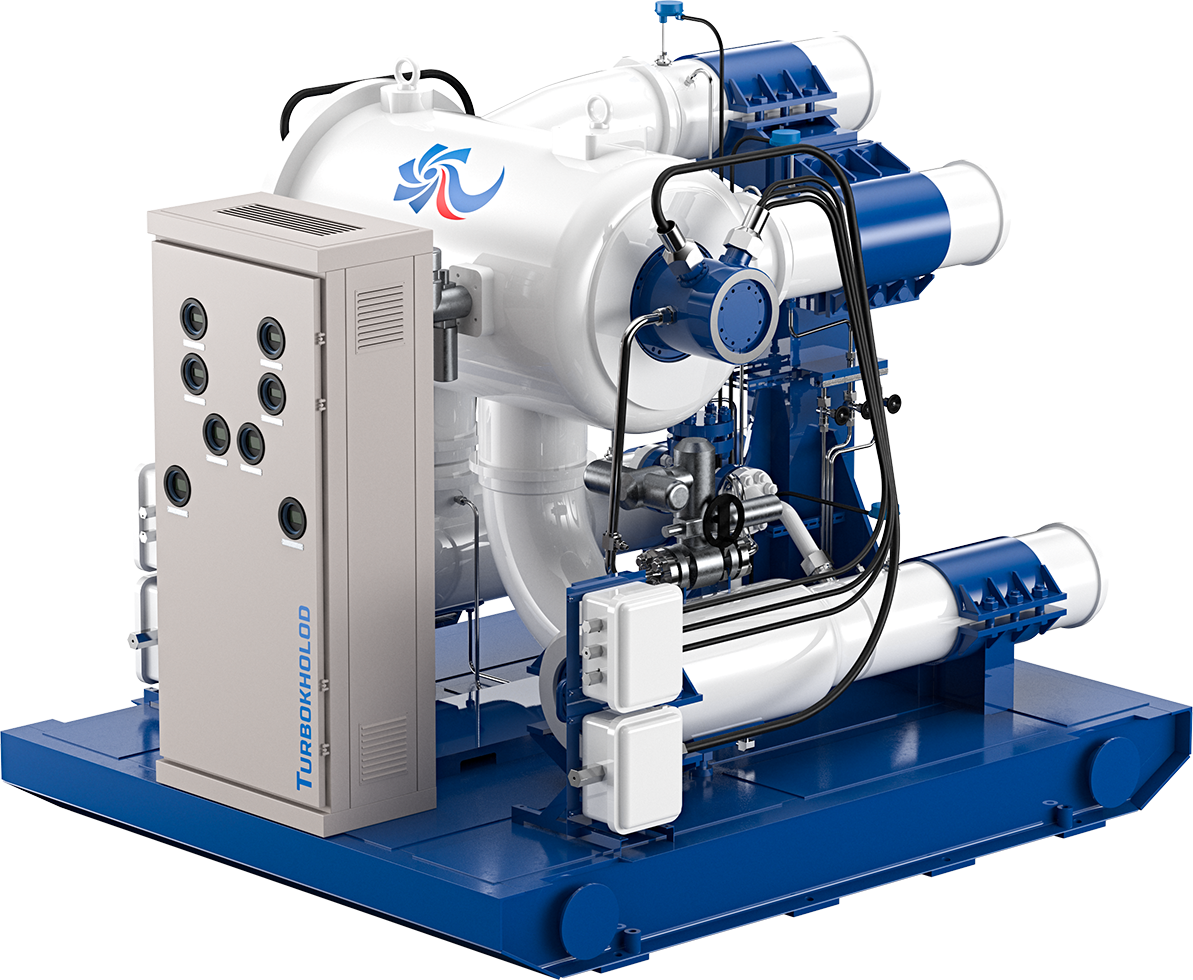

ADKG-10

The basic modification is a monoblock in a mounting frame with tubing, measurement and control instrumentation, and skid accessories -

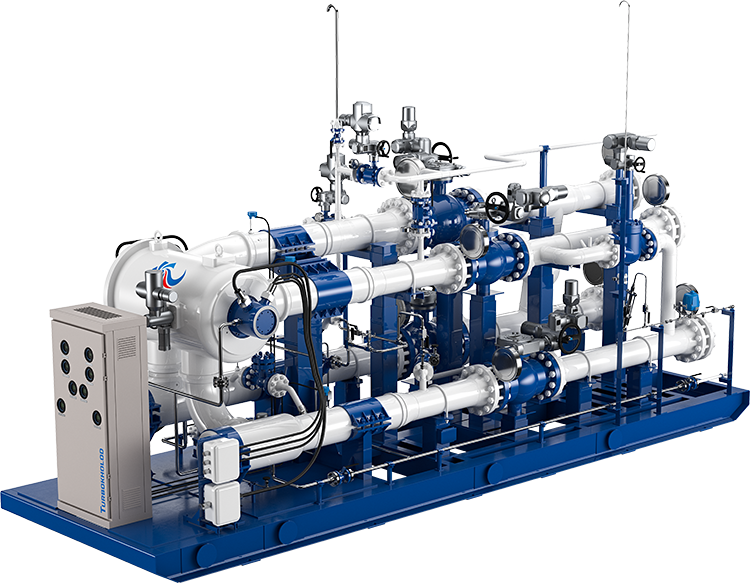

ADKG-10 with valve skid

The integrated solution – a basic unit with a skid of shut-off and control valves in a mounting frame: start-up, protection and bypass without stopping the main production line. -

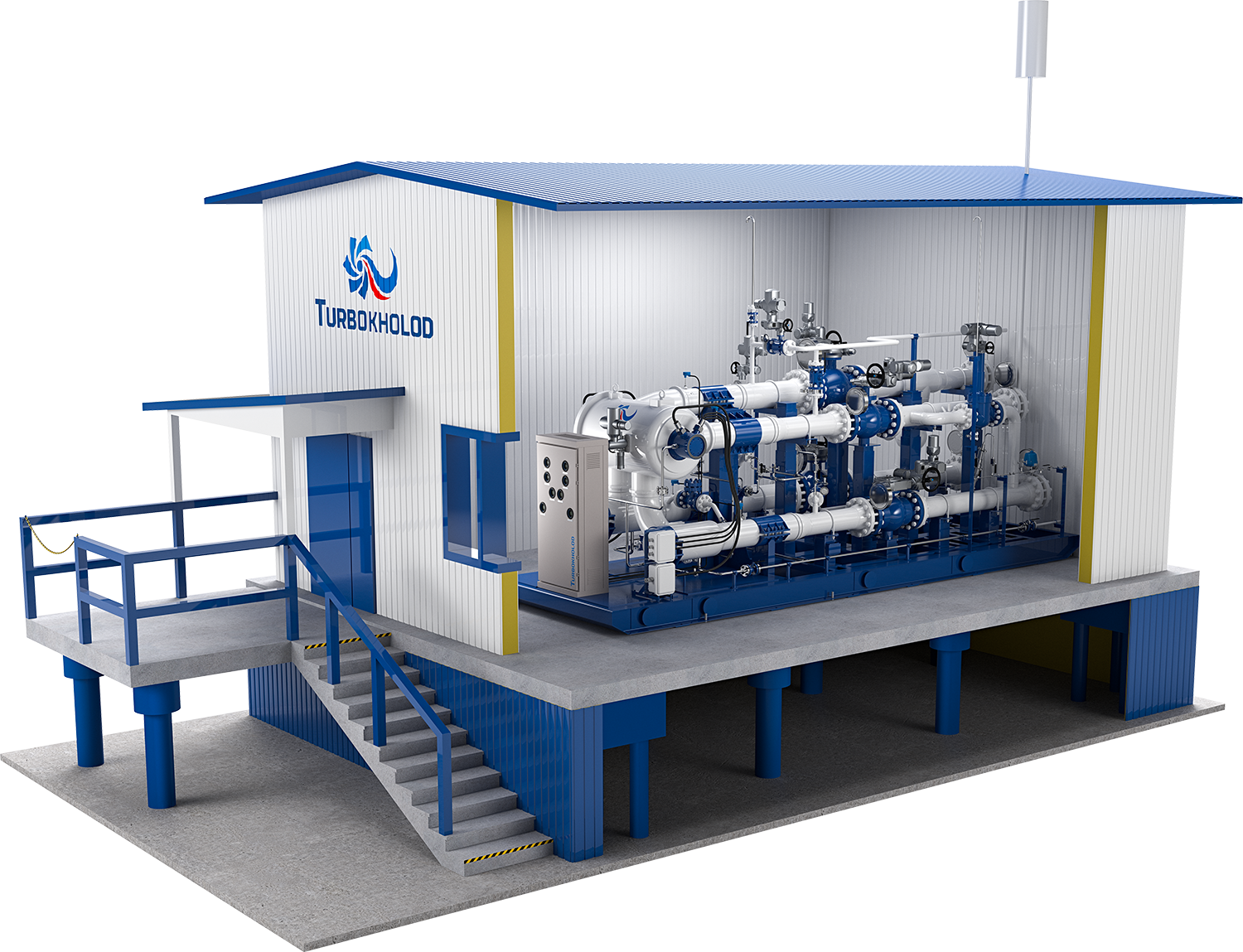

Turboexpander in modular shelter

A comprehensive solution —a basic valve skid unit in an easily assembled modular shelter with engineering systems and small scale mechanization facilities.

| Project | Customer | Quantity | Year |

|---|---|---|---|

| GP 16 SOG Pestsovaya area of the Urengoy Oil and Gas Condensate Field (OGCF) | LLC “Gazprom dobycha Urengoy” | 10 | 2008 |

| Integrated Gas/condensate Processing Plant (IGPP) of Yurkharovsky OGCF | LLC “NOVATEK-YURKHAROVNEFTEGAZ” | 9 | 2008 |

| IGPP 1B, 2B Zapolyarnoye OGCF | LLC “Gazprom dobycha Yamburg” | 7 | 2009 |

| IGPP Nakhodkinskoye OGCF | LLC ”Lukoil Zapadnaya Sibir” | 4 | 2010 |

| SOG KS 42 Yarynskaya | LLC “Gazprom transgaz Ukhta” | 11 | 2011 |

| IGPP Bovanenkovskoye OGCF | LLC “Gazprom dobycha Nadym” | 40 | 2012 |

| IGPP Kharvutinskoy ploshchadi Yamburgskovo OGCF | LLC “Gazprom dobycha Yamburg” | 8 | 2012 |

| IGPP Yurkharovskoye GCF | LLC “NOVATEK-YURKHAROVNEFTEGAZ” | 2 | 2013 |

| SOG KS 42 Yarynskaya | ООО “Gazprom transgaz Ukhta” | 22 | 2014 |

| IGPP Achimovskoye OGCF | PJSC "NOVATEK", JSC "Arktikgaz” | 4 | 2015 |

| IGPP Samburgskoye OGCF | PJSC "NOVATEK", JSC "Arktikgaz” | 7 | 2016 |

| IGPP Yaro-Yakhinsky OGCF | PJSC "NOVATEK", JSC "Arktikgaz” | 2 | 2016 |

| UNTS at the Arslan IGPP | «ENTER Engineering Pte. Ltd. » | 2 | 2019 |